Fragmented data, scattered across departments, hinders companies from making informed decisions. This leads to inefficiencies, wasted resources, and missed opportunities. Integrated data solutions like centralized platforms can transform this data into a unified resource, enabling smarter choices for growth.

In industries like construction, engineering, and manufacturing, fragmented data is a widespread challenge that often leads to inefficiencies, poor decision-making, and limited scalability. Data is generated from multiple sources, from on-site project data to inventory logs and client communications, yet this valuable information is often siloed, resulting in delayed insights and misaligned objectives. As a result, the need for integrated data solutions is more pressing than ever.

In 2024, FMI predicts a 10-20% growth across key segments in construction. However, the industry still faces major challenges with data management. Poor data quality costs the industry over $88 billion annually in rework, and improving data strategies could save up to $1.85 trillion globally .

In this article, we’ll explore what fragmented data is, why it hinders effective decision-making, and how integrated solutions like centralized data platforms, AI-driven analytics, and real-time integration can help. By addressing these challenges, companies can transform scattered data into a unified resource, enabling smarter and faster decisions that drive growth and competitive advantage.

Data silos occur when data is stored separately within different departments or systems, often due to legacy technology, inconsistent data management practices, or lack of communication between teams. In industries where data is generated from various specialized sources, these silos form naturally, making it difficult for organizations to harness a complete view of their operations.

For example, in construction, project management data may be isolated from financial records and supplier information. Engineering teams might store CAD files separately from other project documentation, and manufacturing companies often maintain isolated databases for production, inventory, and supply chain. These barriers prevent organizations from obtaining a unified source of truth, leading to lost opportunities and inefficiencies.

When data is fragmented, decision-makers lack access to the complete picture. Inconsistent information leads to conflicting conclusions, delayed insights, and decisions based on partial data.

This impact is felt across industries:

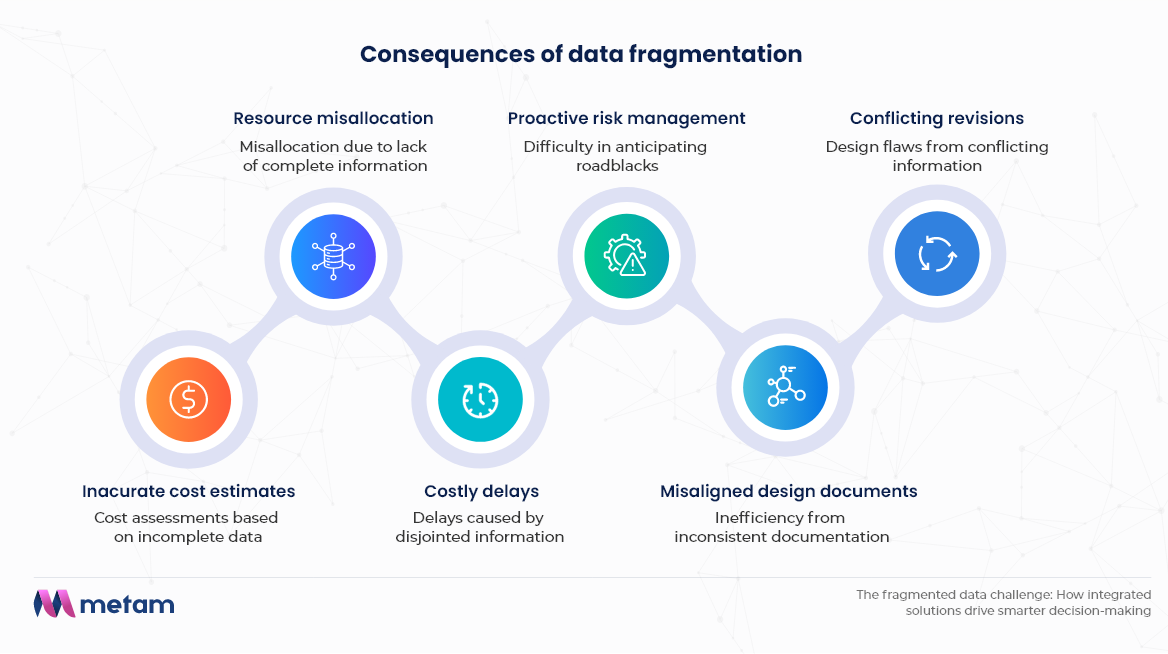

Fragmented project data can result in inaccurate cost estimates, resource misallocation, and costly delays. When teams rely on disjointed information, project timelines suffer, and budget overruns become more common.

In addition, fragmented data prevents proactive risk management, making it harder to anticipate potential roadblocks, ultimately undermining client satisfaction and long-term project success.

Misaligned design documents and client communication reduce efficiency and increase the risk of errors. Without a single source of truth, engineers may encounter conflicting revisions, leading to design flaws or delays in approval cycles.

Furthermore, poor data integration between departments can hinder innovation, as teams may not have access to the most up-to-date designs or client feedback, ultimately delaying product launches and increasing costs.

Inconsistent inventory and production data affect supply chain responsiveness and operational efficiency. Fragmented data across production lines, inventory systems, and suppliers can result in inaccurate forecasting, leading to either overstocking or stockouts. This disrupts production schedules, increases operational costs, and impairs customer satisfaction by delaying deliveries, highlighting the need for seamless data integration to maintain a competitive edge in the fast-paced manufacturing landscape.

Without integrated data, companies struggle to respond to market changes, anticipate risks, and align operations with business goals, placing them at a competitive disadvantage.

A unified data platform serves as a single source of truth, allowing teams across an organization to access and analyze accurate, up-to-date information.

This centralization provides several benefits:

With a centralized data solution, companies in construction, engineering, and manufacturing can reduce delays and optimize resource allocation, ultimately improving project outcomes and profitability.

Data integration strategies, such as APIs and cloud integration, break down silos by allowing data from various sources to flow seamlessly into a central system. In construction, engineering, and manufacturing, this connectivity empowers organizations to synchronize project timelines, maintain accurate records, and share information in real-time.

Integrated data allows organizations to gain a holistic view of operations, enabling proactive responses to challenges and data-driven innovation. Additionally, cloud-based solutions make integration more scalable, allowing companies to adapt to growth and industry changes.

Real-time data integration tools enable companies to capture and consolidate information instantly, providing immediate insights. This is particularly valuable in manufacturing, where real-time monitoring of production lines ensures efficient operations and timely adjustments.

In construction, real-time project management systems keep stakeholders updated, reducing miscommunications and enabling swift course corrections. Such tools allow businesses to respond faster to emerging issues, making data integration a strategic asset.

AI-driven analytics can process massive datasets from diverse sources, transforming raw information into actionable insights. By analyzing trends and patterns, AI-driven systems can predict project timelines, anticipate equipment needs, and highlight inefficiencies.

For example, in engineering, AI-based analytics can help identify bottlenecks in design processes, while in manufacturing, AI tools optimize inventory management and production schedules, minimizing waste. Through AI-driven analytics, organizations turn data into a powerful resource for predictive decision-making.

Integrated data is only as valuable as its quality. Data governance ensures the accuracy, security, and accessibility of data, establishing a foundation for sustainable data practices.

Key elements include:

Adopting these practices enables companies to maintain the integrity of their integrated data systems, maximizing the reliability of their insights.

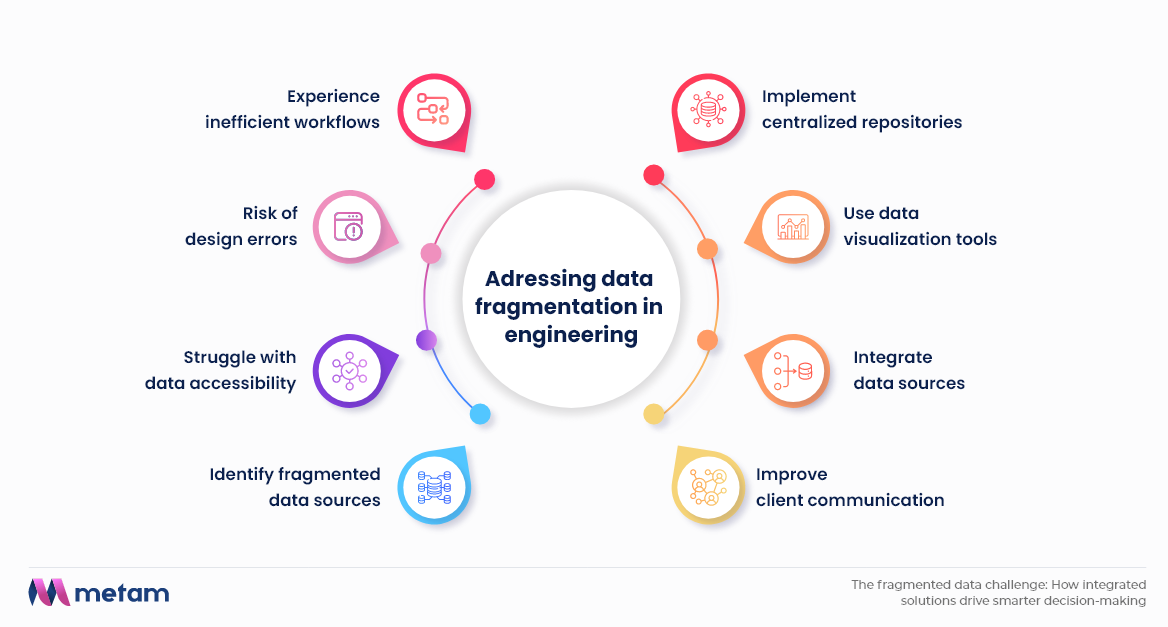

Challenges:

Solutions:

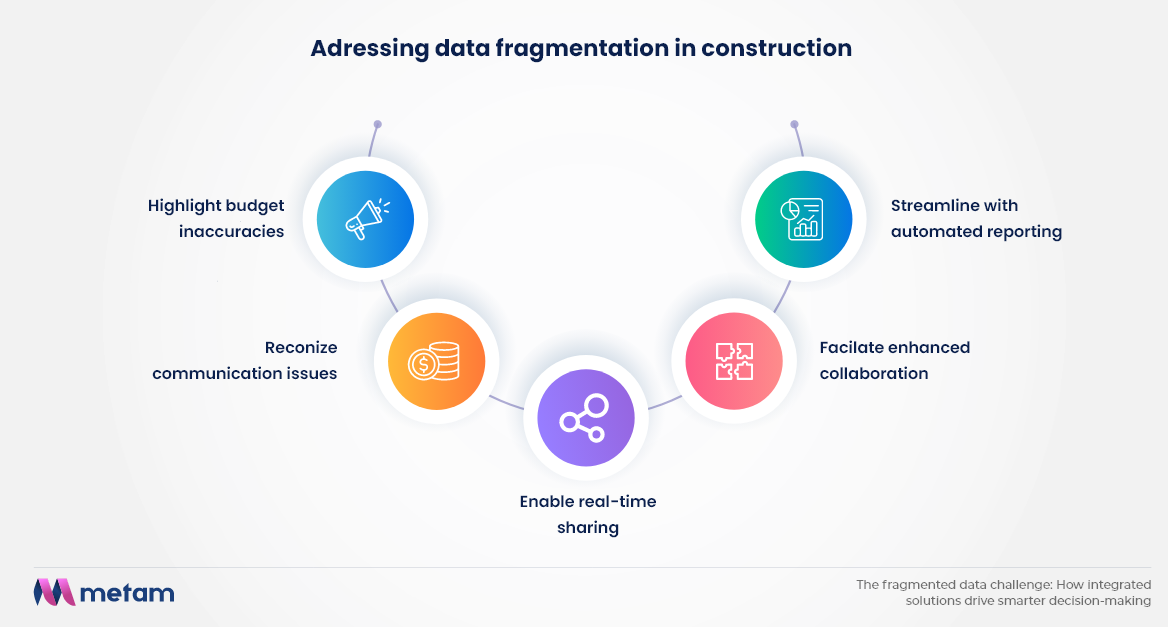

Challenges:

Solutions:

Challenges:

Solutions:

By addressing these sector-specific data fragmentation challenges and leveraging integrated solutions, businesses in construction, engineering, and manufacturing can significantly enhance their operational efficiency, reduce costs, and improve overall outcomes.

Data governance ensures long-term sustainability and reliability of data practices. It includes establishing data stewardship, defining standardized data protocols, and setting up access controls to ensure that only authorized personnel can access sensitive information.

Implementing data governance helps organizations maintain high-quality data that drives accurate, reliable insights.

Selecting the best-fit technology depends on company size, budget, and industry needs. For example, cloud solutions are ideal for scalability, while AI-powered platforms are valuable for advanced analytics. Construction, engineering, and manufacturing companies should assess these factors to choose solutions that align with their data integration goals.

Data-driven transformation may encounter barriers like employee resistance and legacy systems. Addressing these challenges with employee training, gradual integration, and clear communication on the benefits of integration can ease the transition and enhance adoption.

Data security is critical to protect sensitive information and ensure compliance with regulations. Implementing robust security measures, such as encryption, multi-factor authentication, and regular audits, helps prevent unauthorized access and safeguard organizational data.

Ongoing monitoring is essential for ensuring that data systems remain efficient, accurate, and secure. Regular audits, performance assessments, and feedback loops allow organizations to identify areas for improvement and implement necessary updates to maintain optimal data management practices.

At Metam Technologies, we recognize that overcoming the challenge of fragmented data is crucial for organizations in construction, engineering, and manufacturing to drive smarter decision-making and achieve sustainable growth. Our integrated data solutions enable businesses to consolidate and secure their data, unlocking real-time insights, enhancing collaboration, and harnessing the power of predictive analytics.

As industries continue to evolve, adopting these technologies not only enhances operational efficiency but also promotes innovation and strengthens competitive advantages. By integrating data across platforms and leveraging AI-driven analytics, Metam Technologies helps organizations make informed decisions that lead them toward long-term success.