Health and safety challenges in construction and engineering impact both workers and project success. Implementing regulations, risk management, and best practices is essential. Strategic solutions ensure compliance, reduce hazards, and improve workplace safety.

Health and safety challenges are a critical concern in the construction and engineering industries, with the potential to impact both workers and the overall success of projects. These industries are inherently risky, making it essential to understand the key hazards that affect workers on construction sites.

In 2023, the U.S. construction industry recorded 1,075 worker fatalities, the highest number since 2011, highlighting the urgent need for stronger safety measures (Source: Construction Dive). As job site hazards continue to pose serious threats, companies must leverage advanced technologies and data-driven insights to improve workplace safety and reduce incidents.

This article will delve into the key health and safety challenges that construction and engineering professionals face, explore actionable solutions, and provide strategic recommendations to improve workplace safety.

Construction and engineering projects come with numerous health and safety challenges that can significantly impact worker well-being. From physical hazards to mental health concerns, understanding these challenges is vital for mitigating risks and ensuring safe working environments.

Construction sites are inherently dangerous environments, with workers exposed to various physical hazards. The most common include falls from heights, equipment accidents, and being struck by falling objects. These physical risks can be mitigated by adhering to safety protocols and following Occupational Safety and Health Administration (OSHA) regulations.

OSHA mandates specific guidelines for the use of fall protection, scaffolding, and equipment maintenance. However, the challenge remains in consistently enforcing these regulations and ensuring that workers have the right training and equipment. Additionally, high-risk activities such as working in confined spaces or near heavy machinery require strict attention to safety standards and ongoing vigilance.

The psychological toll of construction and engineering work is often underestimated. Stress, fatigue, and anxiety can all affect a worker's ability to perform tasks safely. The industry's culture, which frequently prioritizes deadlines over health, exacerbates this issue. According to a study by the Construction Industry Institute, workers in construction experience higher rates of stress, burnout, and mental health issues compared to other industries.

Recognizing the role of mental health in safety is crucial for reducing workplace incidents. Construction companies can take proactive measures by integrating mental health support into their safety programs, offering stress management workshops, and promoting open dialogue about mental well-being. Providing resources such as counseling services and regular mental health check-ins can also significantly enhance worker performance and safety.

Exposure to hazardous materials is another critical safety issue on construction sites. Substances like asbestos, lead, and toxic chemicals pose severe health risks, including respiratory issues and long-term diseases like cancer. The safe handling, disposal, and storage of these materials are regulated by OSHA, but incidents still occur due to lapses in training or awareness.

Proper ventilation, protective equipment like respirators, and continuous monitoring of hazardous materials can mitigate these risks. Additionally, adopting green construction practices and using eco-friendly materials can reduce exposure to harmful substances, further enhancing worker safety.

Ergonomic risks are another common concern, particularly for workers engaged in tasks that require repetitive motions or lifting heavy objects. These activities can lead to musculoskeletal disorders, including back and shoulder injuries. Repetitive strain injuries (RSIs) cost the industry billions annually in worker compensation and lost productivity.

Employers can address these risks by implementing ergonomic tools and equipment, such as adjustable scaffolding and mechanical lifting aids. Proper training on lifting techniques and posture can also reduce the occurrence of these injuries, contributing to a safer and more efficient work environment.

Staying compliant with health and safety regulations is a continual challenge for construction and engineering projects. Regulations are constantly evolving, and businesses must stay up-to-date with the latest OSHA standards and state-specific laws. Maintaining documentation, conducting regular safety audits, and ensuring workers are trained on compliance requirements are essential to avoid costly fines and legal issues.

The complexity of compliance increases with the size and scope of the project. High-rise buildings and large infrastructure projects present additional challenges, as safety protocols must be adapted to the scale and unique risks of each project. Failure to comply not only jeopardizes worker safety but also exposes companies to reputational damage and legal liability.

Some construction and engineering projects are inherently more dangerous due to their complexity. High-rise buildings, bridges, tunnels, and infrastructure projects often involve significant safety risks, such as working at great heights, operating heavy machinery, and dealing with unstable materials. Managing safety on these types of projects requires specialized knowledge, advanced planning, and strict risk management strategies.

In high-risk environments, it is critical to conduct thorough risk assessments, implement high-level safety protocols, and employ safety personnel specifically trained for these types of projects. Safety teams should work closely with project managers to ensure that safety procedures are followed from planning through to execution.

Adopting effective solutions to address health and safety challenges is crucial in creating safer construction environments. Implementing the right tools, training, and protocols can significantly reduce the likelihood of accidents and injuries.

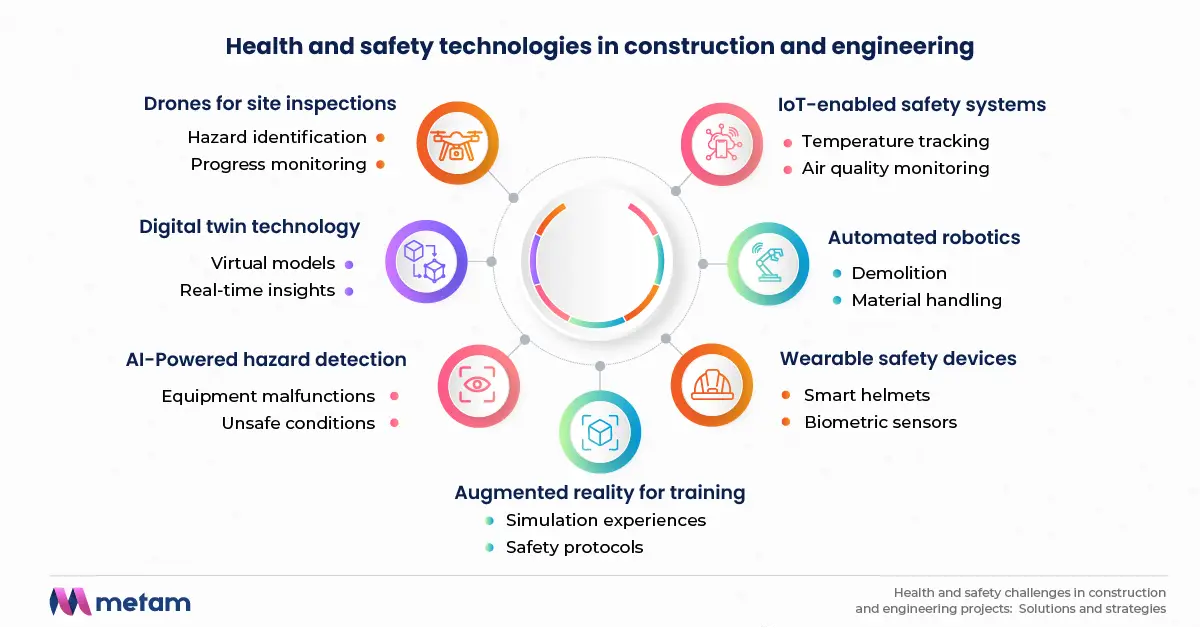

Innovative technologies are transforming health and safety in construction, helping companies mitigate risks and protect workers. Key advancements include:

By integrating these technologies, construction companies can proactively address safety concerns and mitigate risks before they escalate into accidents.

No technology can replace the importance of robust safety protocols and training programs. Safety induction programs should be mandatory for all new workers, and regular safety drills should be conducted to ensure that all employees are familiar with emergency procedures.

Leadership plays a critical role in fostering a safety-first culture. When managers and supervisors actively promote safety, lead by example, and encourage open communication, workers are more likely to take safety seriously. Regular training sessions and workshops on the latest safety standards and practices can further enhance compliance and reduce accidents.

Conducting regular site inspections and risk assessments is essential for identifying potential hazards before they result in accidents. Inspections should be comprehensive and frequent, with a focus on high-risk areas like scaffolding, electrical systems, and heavy machinery.

Risk assessments should be a proactive process, identifying hazards before they emerge and allowing project managers to implement preventative measures. Leveraging technology like sensors and monitoring tools can streamline this process, providing real-time data that can be used to make informed safety decisions.

Health monitoring systems that track workers’ health and well-being are gaining popularity in construction. Wearables that monitor heart rate, temperature, and fatigue levels can alert supervisors when workers need a break or are at risk of injury. These systems provide real-time insights that can help prevent accidents and improve overall worker health and productivity.

Partnering with safety consultants can help ensure that safety protocols are up-to-date and comprehensive. Consultants can conduct customized safety audits, identify areas for improvement, and recommend strategies to optimize safety management. These experts bring a wealth of knowledge that can help companies stay compliant with regulations while enhancing site safety.

Clear communication is crucial for maintaining safety on construction sites. Implementing real-time communication apps allows workers to quickly report hazards, accidents, or near-misses, ensuring a rapid response to potential issues. Incident reporting platforms that automatically generate reports and alerts can streamline the process and ensure that safety issues are addressed promptly.

Proactive strategies are key to creating a safer work environment. By implementing a combination of innovative tools, clear policies, and strong leadership, construction and engineering projects can reduce risks and improve overall safety.

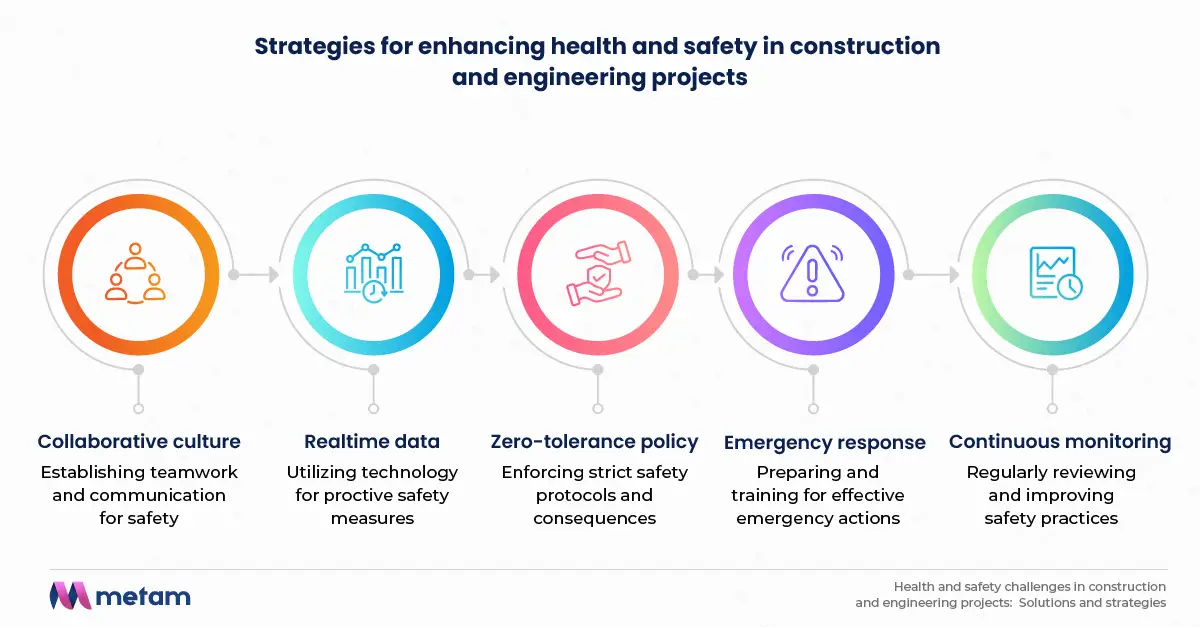

Safety is everyone’s responsibility. Creating a collaborative safety culture that involves management, workers, and engineers is essential for ensuring that safety is prioritized across all levels of the organization. Regular cross-departmental meetings and safety briefings foster open communication, making it easier to identify potential issues and implement solutions.

Real-time data, collected from IoT sensors, wearables, and monitoring devices, offers actionable insights that can be used to continuously improve safety practices. By analyzing this data, companies can identify trends, predict potential hazards, and make data-driven decisions to prevent accidents.

A zero-tolerance policy for safety violations is critical for maintaining high safety standards on construction sites. When workers know that safety violations will not be tolerated, they are more likely to adhere to protocols and be more vigilant about potential hazards. Clear consequences for non-compliance should be established and communicated to all employees.

In the event of an accident, having a well-trained emergency response team is vital for minimizing injury and damage. These teams should undergo regular training to stay sharp and ensure that they are prepared to handle any situation that may arise. Emergency drills should be conducted frequently to maintain readiness.

Implementing continuous monitoring systems, such as safety audits and feedback loops, ensures that safety practices are regularly reviewed and improved. These systems allow companies to identify gaps, track progress, and adjust strategies to enhance safety performance over time.

Health and safety challenges in construction and engineering projects are multifaceted and complex. However, by embracing new technologies, adhering to rigorous safety protocols, and fostering a culture of safety, industry professionals can significantly reduce risks and enhance the well-being of workers.

Metam Technologies offers innovative solutions and services that can help construction companies mitigate health and safety risks. From advanced hazard detection systems to real-time health monitoring, these technologies are transforming safety management on construction sites.

Metam Technologies is leading the way in revolutionizing construction site safety. With AI-powered risk assessments and real-time hazard detection systems, Metam’s platform offers advanced solutions that help companies manage safety more effectively. These technologies allow for instant detection of potential risks, providing real-time data and predictive analytics that can prevent accidents before they occur.

Metam Technologies’ platform integrates seamlessly into existing construction workflows, allowing for a smooth adoption of new safety practices without disrupting ongoing projects. The platform is compatible with industry tools, making it easy for teams to incorporate advanced safety technologies into their daily routines.

Metam Technologies leverages AI-driven analytics and machine learning models to predict potential hazards before they happen. By analyzing vast amounts of site data, AI can identify risk patterns, recommend preventive measures, and optimize safety strategies in real time. These data-driven insights empower project managers to make informed decisions, ensuring safer work environments and reducing costly incidents.

Metam’s real-time monitoring and reporting capabilities play a crucial role in maintaining safety on construction sites. Through continuous, data-driven insights, the platform helps companies stay on top of safety metrics and ensure compliance with all regulations.

The strategies and solutions outlined in this article provide a comprehensive roadmap for improving safety standards in construction and engineering projects. Companies that prioritize safety not only protect their workers but also ensure the long-term success and sustainability of their projects.

Enhancing health and safety in construction requires a blend of advanced technology, strong safety protocols, and proactive leadership. Tools like AI-driven risk assessments and real-time monitoring help reduce accidents, improve worker well-being, and enable quicker response to emerging hazards.

A safety-first culture across all levels ensures continuous improvement, fosters accountability, and promotes compliance. Prioritizing safety not only protects workers but also drives efficiency, reduces costs, and ensures the long-term success of projects.