Metam Technologies is helping construction and engineering companies improve health, safety, and business continuity through digital solutions. By utilizing data-driven insights and AI tools, Metam supports organizations in managing risks effectively, fostering safer work environments, and ensuring operational resilience.

With increasing demands for safety, evolving regulations, and the need for continuous, uninterrupted operations, traditional methods are being gradually replaced by more sophisticated strategies. Digital transformation has become a key driver for improving efficiency and ensuring long-term success in the construction and engineering sectors.

In response to these challenges, we at Metam Technologies recognize the need for strategies that enhance safety and operational resilience in construction and engineering projects. By leveraging advanced technologies, we help mitigate risks, improve efficiency, and support continuous, safe operations. Our approach enables teams to stay ahead of construction and engineering health and safety challenges and maintain project success from start to finish.

This article explores the intersection of technology, health and safety, and business continuity in the construction and engineering industries, highlighting how our evidence-based strategies are addressing critical challenges and helping organizations build more sustainable and resilient operations.

Digital transformation is fundamentally reshaping the construction and engineering industries, particularly in health and safety management. The shift from reactive to proactive safety measures is becoming a critical focus, with advanced monitoring systems and integrated digital tools now playing a pivotal role in managing risks and ensuring the well-being of workers. As the demand for enhanced safety protocols continues to grow, so does the importance of adopting data-driven solutions that improve both safety and operational efficiency.

At Metam Technologies, we recognize the importance of digital transformation in advancing health and safety practices within construction and engineering. By understanding the evolving needs of the industry, we advocate for the integration of real-time data analytics, AI, IoT sensors, and advanced monitoring systems to create a more comprehensive approach to managing health and safety. Our perspective emphasizes how these tools help organizations address emerging risks while sustaining high levels of productivity.

In the construction industry, health and safety are not just regulatory requirements, they are essential for the well-being of workers and the success of projects. Historically, safety management has been reactive, with incident reports and safety audits often conducted after accidents have occurred. While this approach is necessary, it leaves gaps in risk management, as potential hazards may go undetected until it's too late.

The digital transformation in construction is now enabling a shift toward proactive safety measures. Advanced technologies like IoT devices, wearable sensors, and real-time environmental monitoring systems are becoming integral to managing health and safety on construction sites.

At Metam Technologies, we understand that ensuring a safe and efficient work environment requires more than just addressing issues after they arise. We recognize the value of integrating real-time data collection and predictive analytics to help construction managers take preventative actions. This approach not only ensures safer worksites but also helps maintain productivity while reducing accidents and delays.

For the engineering sector, managing safety and ensuring business continuity go hand in hand. With complex projects and high stakes, the need for integrated health and safety management systems is more crucial than ever. Digital solutions, such as predictive analytics and automated monitoring systems, help engineering firms manage risks more effectively, providing insights that mitigate potential disruptions.

Metam is committed to embedding safety into every stage of the project lifecycle. We focus on using data-driven approaches to identify risks early, allowing engineering firms to maintain operational continuity, even in the face of unexpected challenges. Our approach helps engineering teams stay ahead of potential issues, ensuring business continuity and minimizing costly delays.

Metam Technologies acknowledges the critical role business continuity planning plays in the construction and engineering sectors. With the knowledge that disruptions, whether caused by natural disasters, economic shifts, or unforeseen events, can impact productivity, Metam highlights the importance of strategies that help organizations maintain resilience and ensure operations continue without interruption.

We emphasize the need for proactive solutions that enable construction and engineering companies to address potential risks, streamline crisis response strategies, and implement redundancy systems to protect against disruptions. By integrating technology and data-driven insights, we aim to support businesses in developing continuity plans that are robust, adaptable, and designed to sustain long-term success.

Business continuity planning is an essential aspect of risk management that requires a comprehensive approach. At Metam Technologies, we are committed to supporting construction and engineering companies by offering a strategic approach to business continuity planning.

A resilient continuity plan relies on several key components:

By addressing these elements, organizations in construction and engineering can build resilience and transform potential setbacks into manageable challenges, a philosophy Metam Technologies firmly supports. By focusing on resilience, we help ensure long-term success, even in unpredictable environments.

Operational resilience is not achieved by addressing risks in isolation but by embedding digital integration throughout the project lifecycle. At Metam, we emphasize the importance of centralized data integration from multiple sources, such as IoT devices, project management systems, and regulatory databases, providing a unified view of operations. This comprehensive approach allows for rapid, informed decision-making and ensures alignment with strategic objectives across all project stages.

Continuous monitoring through advanced analytics is a critical element of this integration. Real-time insights allow for immediate detection of anomalies and swift corrective actions, reinforcing the overall stability of operations. Digital collaboration platforms further enhance this resilience by breaking down traditional silos and enabling cross-functional teams to work in unison. Together, these integrated systems create a robust operational framework that can absorb shocks and capitalize on emerging opportunities.

Effective risk management is central to business continuity planning. At Metam, we emphasize the need to identify potential risks early and prioritize them to develop strategies that reduce the impact of disruptions.

This proactive approach ensures that construction and engineering companies can navigate challenges with minimal downtime, keeping projects on track and maintaining productivity. By continuously monitoring and utilizing predictive analytics, we enable teams to adjust strategies as conditions evolve, further strengthening project resilience and efficiency.

When disruptions occur, having a clear, well-defined crisis response strategy is crucial. Metam understands the importance of streamlining crisis management for construction and engineering firms, especially through the integration of digital solutions.

By automating response protocols and providing real-time data, we help teams mobilize quickly to minimize disruptions, ensuring that critical operations continue without delays. These solutions also support better communication across teams, ensuring that everyone is aligned and ready to respond swiftly, reducing potential losses and maintaining business continuity.

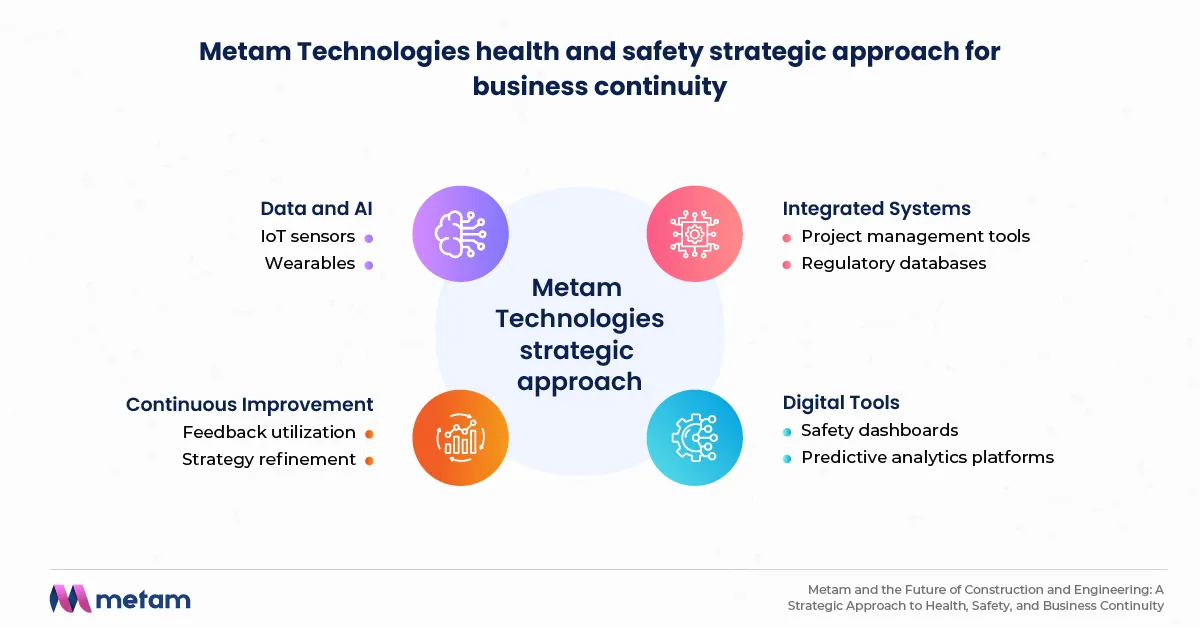

A comprehensive strategy for health, safety, and business continuity must address every stage of project management, from risk assessment to crisis recovery. We understand the critical importance of integrating digital solutions to strengthen safety protocols and ensure operational resilience in construction and engineering.

As the industry continues to evolve, we focus on a strategic, data-driven approach that combines technology with practical risk management. Our commitment to leveraging data, AI, integrated systems, and continuous improvement reflects our awareness of the industry's needs for enhanced safety and long-term business continuity.

By incorporating advanced digital tools and continuous monitoring, we appreciate the value of enabling construction and engineering companies to proactively manage risks, improve safety, and maintain smooth operations throughout the project lifecycle.

As the construction and engineering industries face increasing complexity, the integration of digital technologies into health and safety protocols and business continuity planning has become indispensable. Metam Technologies stands as a trusted partner, helping organizations navigate this transformation.

By combining advanced digital tools with practical, data-driven strategies, we focus on enhancing safety and fostering operational resilience. Our proactive approach helps businesses anticipate risks, streamline operations, and maintain continuity even in the most challenging environments. We aim to support construction and engineering firms in ensuring safer, more productive workplaces while positioning them for long-term success.