This article explores how digital technologies are revolutionizing OSHA compliance in the construction industry. From AI-driven safety tools to wearable tech, it offers actionable insights for staying compliant while leveraging new technologies to ensure worker safety.

The construction industry is evolving rapidly, with advancements in technology reshaping how safety and compliance are approached. At the same time, the Occupational Safety and Health Administration (OSHA) continues to enforce its critical standards to safeguard workers. With the adoption of digital tools, ensuring OSHA compliance has become more complex but also more efficient.

According to a 2025 study by the Occupational Safety and Health Administration (OSHA), over 30% of construction firms are still behind in utilizing digital tools to ensure compliance with safety regulations.

This article explores how digital tools such as AI, drones, wearable tech, and other innovations are reshaping the process of OSHA compliance and enhancing safety on construction sites. It also provides insights into the challenges construction professionals face in implementing these technologies and strategies to overcome them for long-term compliance.

Construction site safety is regulated by a range of OSHA standards designed to protect workers from a variety of hazards. The role of these regulations is to ensure that workers are not exposed to undue risks while on the job. Comprehending these regulations is vital for preventing accidents, injuries, and fatalities on the job site. The introduction of digital tools into construction safety management brings about new considerations in ensuring compliance with these established OSHA guidelines.

The Occupational Safety and Health Administration (OSHA) is a regulatory agency dedicated to ensuring safe and healthy working conditions across various industries. Established under the Occupational Safety and Health Act of 1970, OSHA sets and enforces workplace safety standards while providing essential training, education, and compliance assistance.

In the construction industry, OSHA regulations play a critical role in preventing workplace accidents by addressing key hazards such as falls, hazardous materials, electrical risks, and unsafe machinery. Compliance with OSHA standards not only reduces injuries and fatalities but also enhances workplace productivity and legal compliance for businesses.

OSHA standards for construction safety are designed to protect workers from a range of physical, chemical, ergonomic, and biological hazards. These standards cover everything from the safe use of equipment, handling hazardous substances, and fall protection to ergonomics and general site management. OSHA regulations are strict, and failure to comply with them can result in significant fines and, more importantly, jeopardize the safety of workers.

Employers must assess risks regularly, provide appropriate protective equipment, and ensure that workers are properly trained to minimize exposure to potential hazards. Compliance with OSHA regulations requires continuous oversight and adaptation, which is where digital tools come in, helping track, manage, and document safety measures efficiently.

Among the most crucial OSHA regulations for construction safety are those related to fall protection, personal protective equipment (PPE), and hazard communication. These standards are critical to reducing risks on construction sites, where falls from heights, exposure to hazardous substances, and physical injury from equipment are common.

The integration of digital tools into construction safety practices is transforming how compliance is monitored and maintained. Digital tools like AI-powered safety management software, real-time data tracking, and automated reporting systems help construction companies stay compliant with OSHA standards. These tools can analyze large datasets, track safety violations, and even provide predictive analysis to foresee potential risks, making it easier to manage safety on large, complex projects.

However, construction professionals must ensure these technologies are integrated properly to avoid issues with data privacy, cybersecurity, or compatibility with older safety systems in place. When used correctly, digital tools help companies meet OSHA requirements more efficiently, with improved accuracy and fewer manual errors.

Integrating modern digital tools with traditional construction safety practices presents significant challenges. These include ensuring that new technologies align with existing OSHA regulations, addressing legal concerns, and ensuring workers have the right training to use these tools effectively. Construction professionals must strike a balance between embracing new technology and staying within the framework of OSHA standards.

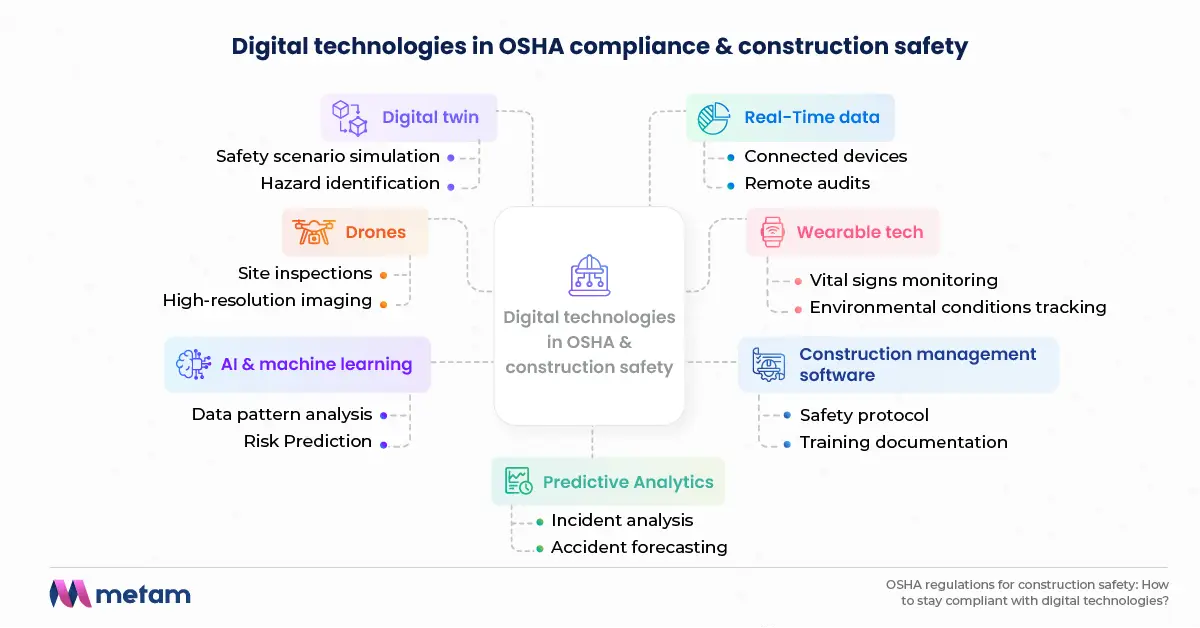

Digital technologies are fundamentally changing how construction safety is managed. From real-time monitoring to predictive analytics, these tools are not only helping to maintain OSHA compliance but also improving safety outcomes for workers on site. These are key digital innovations that are driving the transformation:

While digital tools can enhance safety compliance, they also come with challenges that construction firms must address. From technical limitations to worker resistance, these obstacles can delay the adoption and effectiveness of digital tools in ensuring OSHA compliance.

One of the key challenges of using digital tools for OSHA compliance is ensuring that these tools work seamlessly with existing systems. Compatibility issues can arise, particularly when older systems are involved. Additionally, the handling of sensitive data, such as workers’ health metrics or safety incident reports, raises privacy concerns that must be carefully managed to comply with legal standards.

For digital tools to be effective, workers need to be properly trained on how to use them. Without adequate training, digital tools can fail to prevent accidents or may be used incorrectly, leading to safety violations and non-compliance with OSHA regulations. Ongoing training programs are essential to ensuring that workers are equipped to use the latest technologies safely.

Many construction firms still rely on paper-based systems to track safety protocols and compliance. Transitioning to digital solutions often requires significant time, effort, and investment to integrate old systems with new technologies. Firms must also ensure that all data is accurate and accessible during audits and inspections.

While the benefits of digital tools are clear, the upfront cost of implementing these systems can be a barrier for smaller construction companies. However, the long-term return on investment (ROI) is substantial, with digital solutions helping to reduce the number of safety incidents and OSHA violations, which in turn lowers costs associated with fines, legal fees, and insurance premiums.

The rapid pace of technological advancement in the construction industry means that construction professionals must stay up-to-date with the latest innovations. This can be challenging, especially for firms that are already struggling to integrate existing technologies. Ensuring that safety tools remain compatible with emerging technologies requires continuous investment in both time and resources.

Resistance to digital transformation is a common challenge on traditional construction sites. Workers may be unfamiliar with or distrustful of new technology, and managers may be hesitant to adopt unfamiliar tools. Overcoming this resistance requires a cultural shift within the company, where employees are encouraged to embrace technology and understand its role in improving safety and compliance.

To ensure ongoing OSHA compliance, construction professionals must develop strategies to integrate and monitor digital tools effectively. Below are some practical approaches to maintaining compliance and improving safety standards.

Digital technologies are transforming OSHA compliance and safety management in the construction industry. Tools like AI, wearable tech, and drones offer significant advantages in tracking compliance, identifying potential hazards, and improving overall safety outcomes. However, the adoption of these technologies comes with challenges such as training, budget constraints, and resistance to change.

By selecting the right tools, providing ongoing training, and ensuring seamless integration, construction professionals can meet OSHA requirements, enhance worker safety, and embrace the benefits of digital innovation.